Back in the spring of 2023 it was clear that my stock of inky-blue and gold merino cloth was running low.

So, looking ahead to the coming winter, I embarked on the process of designing and commissioning a new shirt fabric.

Our original merino cloth was woven for us at the specialist flannel mill, Melin Teifi. Having produced exceptional cloth for over 50 years, expert weaver Raymond Jones has now, deservedly, retired from commission weaving.

So, I made alternative enquiries.

We are extremely lucky to still have one other commercial mill in Carmarthenshire that will produce short runs of woollen cloth to commission. It is here, at Curlew Weavers that my local Ryland and Black Welsh Mountain fleeces are transformed into the exceptional herringbone tweed that I use for our Cambrian Gilet.

However, due to various logistics including high demand, loom set-ups and yarn specifications, it was becoming clear that having our own shirt fabric woven there was not so straightforward.

I took a shot in the dark and made contact with Daniel Harris of London Cloth who is renovating the crumbling Elvet Woollen Mill, which is also less than an hour from the studio. He invited me down to see how they are getting on with the project and very generously helped me to brainstorm my predicament.

The project he has taken on is a mammoth one, and in short, they are a long way from offering a bespoke weaving service there. Although there was a chance Daniel might be able to squeeze a run of cloth in for me on a suitable loom it was clear that this would be a favour, and for such a short run, the yarn sourcing was problematic… it all, ultimately boils down to economy of scale…

The backbones of the Welsh textile industry are both its treasures and its torture. As far as I know, all of our mills except Melin Tregwynt, run on beautiful but geriatric looms, many of them now around 100 years old. While other parts of the UK - and the rest of the world - invested in new machinery and upped their production capacities, rural Wales, for a blurry, myriad of reasons, chugged along with what they had.

Daniel told me that, using one of these old looms, it can take a few days to weave the same amount of cloth that a modern loom can produce in about 3 hours. Oh.

Of course that also means that if I were to commission cloth woven on a modern, high-speed loom I would be looking at minimum order quantities in the thousands of meters (I was hoping to order 60).

If I triple my order I might be able to approach a cost per meter that makes it possible to produce a shirt that doesn’t require a mortgage to buy. This would mean outsourcing garment production because I’d never be able to make that many shirts by myself, which in turn means a lot more pressure to sell shirts. Hmm. I spy ‘over-stock’ margins and marketing ploys… This is beginning to sound a lot like the fashion industry that I ran way from. That’s not to suggest that I am against growing my business, I just want business growth that is lead by demand, not by trying to push clothing on people who don’t need it just so that I can reach production quantity margins.

I don’t mind admitting that I have a sort of rosy nostalgia for our local wool industry. I want to be able to produce clothing that connects me to where I live. Sense of place and of belonging is deeply important to me in finding value in my work and part of that is using our small, local mills. They connect me to the past generations of people that have eked out a living in these valleys by farming and processing wool, and the wool in turn connects me to the land itself.

In fact, this is so important that I believe it is worth the cost to be able to fully process my local wool into garments that become so loved they are like old friends.

But what about the non-local wool? Our shirt merino was woven at a Welsh mill but was farmed in Argentina. At the time I wanted to balance our cultural heritage of Welsh flannel with a fibre that felt luxurious and soft enough to wear next to the skin. A merging of textile resources…

Humans have traded textiles for as long as we have walked the earth. We have exchanged techniques, merged ideas, traded dye plants, animal skins and clothes themselves, and all the while this exchange of textiles has been synonymous with the exchange of stories and influencing of cultures.

I believe there are still stories to be told through the clothes we wear. If we take the time to tell them and to listen, to make those connections, what a great richness we could feel when dressing for our day.

Unfortunately, the scale of today’s global fashion industry is so mind boggling that it is extremely hard to glean any kind of story or connection to how your clothing is produced. It hasn’t arrived with a trader with tales to tell of French lace-makers or Indian block printers. It arrived on a pallet along with hundreds of other pallets on a ship from a chain of faceless factories.

We all hear the horror stories of the millions of tonnes of clothing waste that gets dumped in Ghana or Chile. In fact those of us that care about these issues of waste and exploitation become so aware of this poisoning that it is almost crippling.

The textile waste mountain in Accra, Ghana - the last resting place of unwanted clothing from the UK market. Image credit: ITV

How on earth can one justify making more clothing a in a world that is already oversaturated?

Because we need a brighter vision.

There needs to be an alternative option; a small-scale alternative to mass production, a local alternative to globalisation, a natural fibre in place of synthetic; a connection.

By working small scale I can pay attention, both to my customers needs and to my materials –to where they are from and how they are made, to how I use them and what happens to the waste.

I don’t have the time to make tiny things from the offcuts of dressmaking because I am focused on doing the things that I am good at, but I still can’t bear to compost the pieces that I know could be turned into something. So, I give them away to friends who craft them into beautiful things like quilted baby blankets or children’s waistcoats.

Whilst brainstorming my shirt fabric predicament with Daniel at Elvet he mentioned a guy who traded ‘deadstock’ yarns and suggested rummaging through his stock as a cheaper source of high-end yarn.

Deadstock is becoming an increasingly popular term, and I have been reluctant to get on that particular train, as I don’t want to support an industry fuelled on overproduction (buying up fabric that was produced for a fashion company, who then decided it wasn’t the exact shade they wanted, doesn’t make you more ethical, it just makes it possible for the mill to continue to be subjected to the whims of big business).

Ends of cones at Melin Teifi, left over from my cloth order

However, the yarns this guy had were mostly a few cones of a colour or blend that was no longer being produced and weren’t of enough quantity for a full run of cloth (or for the producer to sell as it wasn’t a whole box etc). This means you’d have to design a cloth based on what yarns you could gather together instead of starting with a colour concept at the drawing board. OK, not an unappealing challenge…

This made me think of my own scraps and the local crafters inventing a future for them. That too is using ‘deadstock’ on a smaller scale.

Following this train of thought I phoned a man in Yorkshire, who’s family has been trading in reclaimed textiles and shoddy waste since 1905 to chat through my thoughts and reservations. Over many years they have developed good relationships with some of the most highly respected mills not just in the UK but also Italy. These mills produce incredibly fine fabrics for fashion houses all over the world. Once the design house has predicted their garment quantities they work out the fabric requirements and commission the mill to produce it. The cloth goes to the factory where it is layered up on a bed so the pieces can be cut many at a time before going on to sewing. This high scale process means that after production there are usually small ends of bolts left over, perhaps 2m to 10m pieces, that can’t be used as the factories just aren’t set up for it. They are just scraps.

I guess there is always a bigger fish in the sea, with bigger scraps.

Being a smaller fish with a different business model (one that requires a much smaller marketing budget, for example), I can make garments just a few at a time.

Using industry ‘scraps’ also means that I can get an extremely high end fabric at a level I can afford; the cloth has already been paid for by the fashion house, so the price of those scraps to me reflects the costs involved in paying someone to maintain relationships with the mills to save the ends of bolts from landfill and redistribute them to people who can use them.

I requested some samples of the pure wool fabrics that they had in the warehouse and was smitten.

As long as I can get it processed I will never stop using our local wool. For me this is a tether to the land that holds me. It is grounding and visceral, a physical connection to the hills and the people that make my home. But we do not exist in isolation.

From this grounding point I want to explore the stories that connect us to our past and future through people and landscapes. I believe that textiles can carry those stories and make our lives richer.

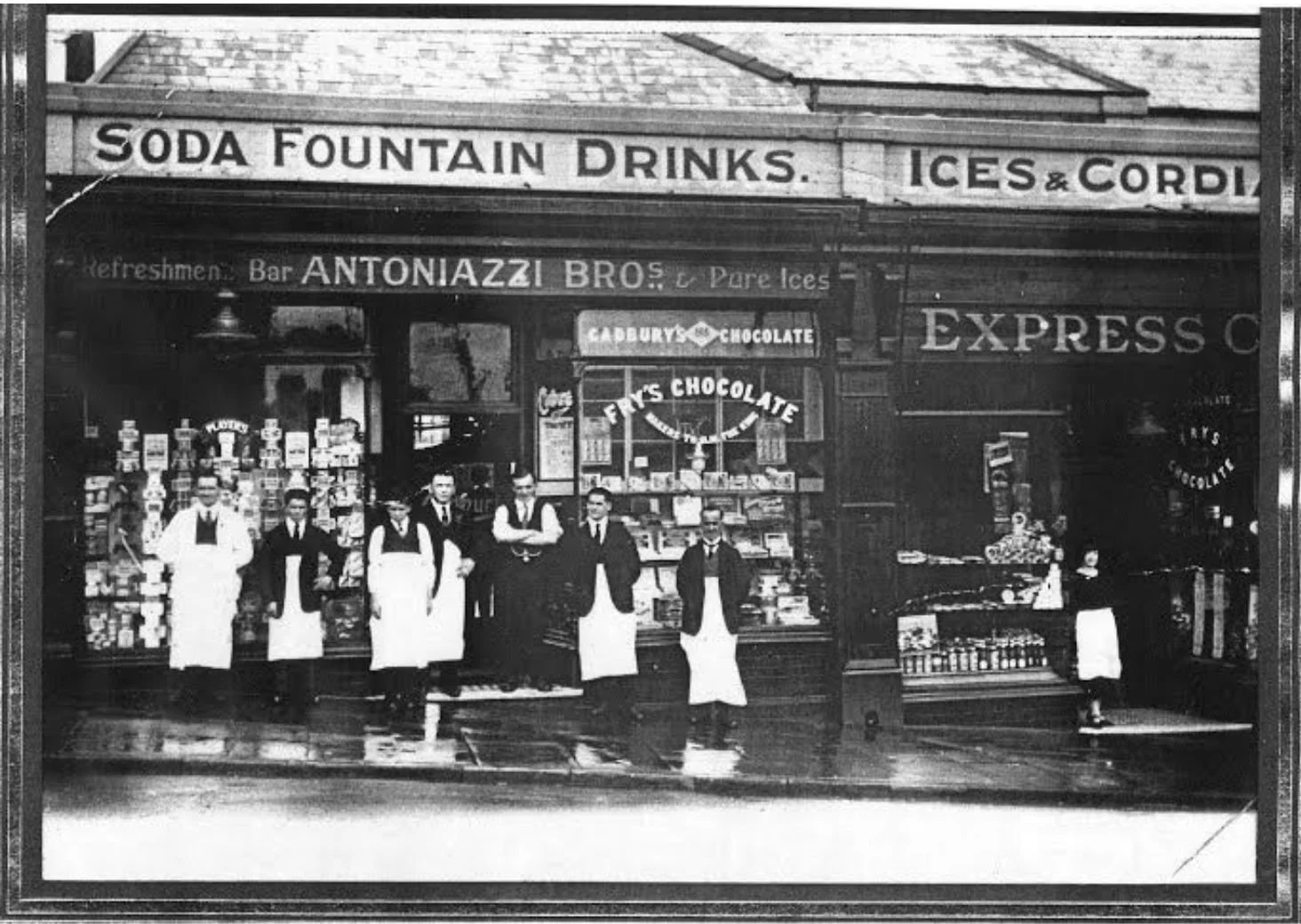

Our first shirt in an ex-designer, Italian fine wool deadstock cloth will be available this autumn 2024 and it will tell the story of Italian migrants who made their way to South Wales at a time of industrialisation and black gold…

Image: St Fagans & the ACLI-Enaip Italian Memories in Wales project - from the BBC Blog

Stay signed up to our mailing list or follow us on Instagram for notification.